Axe Sheath & Hatchet Sheath Handmade DIY

An axe sheath - hatchet sheath is handmade in this step by step DIY hatchet cover article. This snug fitting leather axe cover design protects you and your axe blade. Learn how to make an axe case & hatchet cover with the required leather craft tools.Leather hatchet sheath and double head axe sheath custom made.

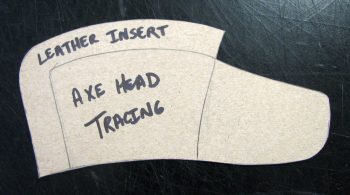

Tracing the blade1. Place the axe on a thin piece of cardboard and trace the blade. An average measurement is around two inches in from the blade tip. Since this axe sheath is not covering the entire head of the axe, you only need to trace the three sides which are the blade edge shown on the top and the left/right side of the head in the following photo.

Adding Space For The Rivets2. This hatchet sheath is designed in a way that protects your blade from the rivets to prevent damage. For this, we add a third layer of leather for the blade to rest against. Take your tracing of your blade and add 5/8 inch to the surrounding edge. Although there are three sides to the tracing, you only do this to the top and blade sides. The handle side will be where the blade slides into the sheath. On that side you are going to draw a tab to fold and snap the blade secure onto the case.

Cutting The Leather Hatchet Sheath3. Next step is to trace the pattern you have created onto your leather. You want to make sure your sheath will be strong, so use 9 ounce tooling leather. 9 oz thick leather is 9/64 inches thick. First you must flip the pattern over and trace this on the leather. It is important to do this so the top grain side of the leather is always facing out. Next, cut the tab off the pattern and trace it on the leather. DO NOT FLIP this part. Lastly, separate the leather insert piece from the axe head tracing and trace your insert piece on the leather. The leather is easily cut with a utility knife on a cutting pad. I will refer to this leather insert piece in the rest of the article as a welt. Coloring Leather4. You can dye, neatsfoot oil and polish the leather to give it a nice finish immediately after you cut the leather shapes being careful not to get oil on the areas where you will glue as glue does not stick well to oily leather. However, in this example we just applied pure neatsfoot oil with a cloth or sponge and polished it with Fiebings resolene just before we set the rivets. The neatsfoot oil gave the leather the nice deep tan color. When using leather dyes it is best to avoid the flamable types if you are buying outside your own country as they have to be shipped by special means which can be expensive. Stick to the nonflammable leather dyes and leather finishes. Also wear protective gloves and use in well venitilated areas. Gluing your pieces together5. You want to make sure you rough up the areas where glue will be applied to the hatchet sheath. A low grit sandpaper will do the trick. This inside leather welt piece protects the sharp blade from being damaged by preventing the axe blade from touching the metal rivets.

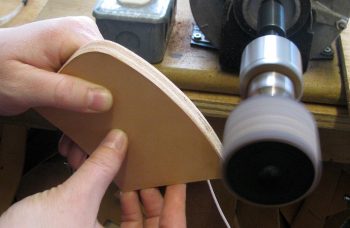

Sanding Edges Of Your Hatchet Case6. After the gluing stage, sand the edge of the three layers even on a drum sander or by hand.

|

Beveling Edge Of Leather Axe Sheath7. The leather edges can be beveled with a hand beveler tool or sanded by hand to round the square edges.

Holes for Rivets8. The most common way to put holes in leather is to use a drive punch but you can also drill them. The more layers of leather, the harder it can be to punch a hole perpendicular through such a combined thickness of material. If you have a drill press it can make this process much easier.

Setting Rivets In Your Axe Sheath9. There are a few types of rivets you can use for this project. We suggest you use Double Cap Rivets X Large for going through three layers of 9 oz thick leather. If you use thinner leather, you might have to use a shorter post rivet such as large double cap rivet. These types of rivets are very strong and have the same finished cap on both sides when set. You can use a rivet setter to achieve a rounded surface on the top side or you can use a cobbler’s hammer, which leaves the rivet head flat on both sides. A cobblers hammer has a slight convex head so it does not mark or damage the leather surface. However, a carpenter's hammer would set the rivets as well. Either way, just make sure there is a solid metal surface to set them on that does not have any bounce.

Setting the Snap Cap10. The last step to making your hatchet sheath is to set the snap. For 9 oz thick leather, use the line 24 large jacket snaps with a long post. For thinner leathers, use the large size snaps with the regular post. This is done by first setting the cap part of your snap in the leather tab. The cap is the part of the snap you push with your thumb. To locate where the cap should be set, measure around ¾ inch from the tip of the leather tab and mark it in the center. Punch the hole with a drive punch. Next you put the axe in the case and fold over the tab on to the body of the case. Use a pencil and make a spot through the hole onto the body of the case. Now you can set the cap of the snap. First put the snap cap post through the hole. Put a dot anvil under the cap to keep the cap's curvature. Put the socket through the cap post and strike the line 24 durable snap setter with a hammer to crimp the post around the socket. Setting the Snap StudBefore you punch the hole in the body, make sure you put a thick scrap piece of leather inside the axe sheath. This will prevent you punching the hole right through the back of the case. The last step is to set the stud part of the snap. Put the snap post through the hole. You need to slide a strong metal surface into the axe case and under the snap post such as a mini anvil. A solid non bounce metal surface is required to ensure the snap will be set properly. Place the stud trough the post and set it with the line 24 durable dot setter. The dot anvil is not required to be used for this part of the snap as you want a flat surface.

You are finished!

|