Custom Leather iPhone Case & Smartphone Case Handmade

Leather Used For Custom Leather iPhone Case

Our handmade custom leather iPhone case is made from rugged natural tooling leather and lined with goatskin. The thickness of the undyed tooling leather is 5 - 6 oz thick (5/64 - 6/64 inch thick) and the goat skin is about 2 oz thick (1/32 inch thick) used in the leather smartphone case. The following steps shown on how to make a hard leather cellular case applies to both custom iphone cases and custom smartphone cases.

Custom leather iPhone Cases handmade and molded to the shape of the cellular phone.

Molding The Custom Leather iPhone Case

The first step in hand making the custom leather iPhone case is to accurately measure your smartphone. Next, make a block from wood or plastic that is the same size. Attach a spacer to the block such as a piece to 6 oz leather to give a little extra room for the phone when molding the leather. This extra room will make it easier to pull the cellular phone out of the cell case.

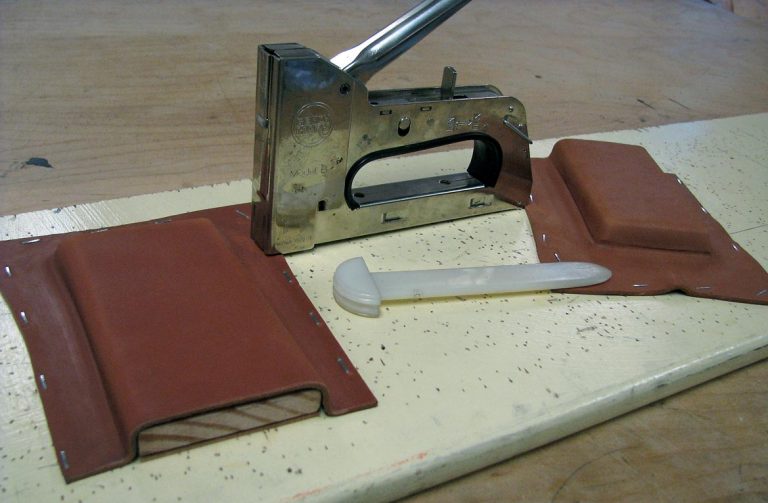

The natural tooling leather is placed in a bucket of water for about 10 minutes so it is thoroughly soaked through. Then the leather is stretched over the block with the help of a white plastic bone folder. When it is almost formed, staple the molded leather over the block, fine tune the shaping and let it dry over night.

Molding custom leather iPhone case with a white bone folder.

Trimming The Leather

The amount of lip required for sewing the front to the back of the leather case is marked. A utility knife or box cutter is used to trim the excess off the lip of the leather.

Trimming leather lip on cellular case with a utility knife.

Dyeing Custom Leather iPhone Case

The natural full grain leather is dyed with an alcohol dye such as Fiebings Oil Dye or Eco-Flo Leather Dye. The leather dye can be applied with a cloth or sheep's wool wrapped over a wooden block or with a wool dauber.

One main difference to consider when buying leather dye is how it can be shipped. Since the Fiebings Pro Dye or Oil Dye is flammable, it can't be shipped between Canada and the United States through the postal system. We can ship it through the postal system if we ship to a Canadian customer since we are located in Canada. It has to be shipped by other couriers between Canada and the United States which are more expensive. However, the Eco-Flo Leather dye is not flammable and can be shipped inexpensively through the postal system between Canada and the United States.

After the leather dye dries, a leather conditioner such as neatsfoot oil is applied to the top surface of the leather. When that is dry, a couple coats of polish such as resolene can be applied to give it a nice sheen.

Leather used to make iPhone case is dyed by hand.

Setting Snap In Leather Smartphone Case

Small jacket snaps set great in 5 - 6 oz thick leather. A sturdy anvil on a solid surface is used with the snap setter so there won't be any bounce when tapping with a hammer. A goat skin liner is glued on the inside of the case on top of the under side of the snap. This will protect the smartphone from coming in contact with the metal snap. A goat skin liner is also glued over the rivets on the back piece of the custom cell case for the same reason.

Setting snap in a leather smartphone case.

Making Finger Holes In Leather Smartphone Case

To make it easier to take the phone out of the case, finger holes are punched in the leather sides of the case. If the phone is too wide or is positioned horizontally in the case, you fingers may not reach wide enough to grab the phone. In that situation, finger holes are punched in the bottom of the case so the phone can be pushed upward to be able to grab.

Hole punch tool used to make finger holes.

Sanding Edge Of Custom Leather iPhone Case

The front and back of the handmade iPhone case are glued together with contact cement. Next, a drum sander is used to sand smooth the leather edges. The beveler hand tool is then used to round the leather edge by removing the leather from the corner edge of the leather.

The edge can be dyed black with Fiebings Edge Kote or another leather dye. It can then be burnished smooth with some beeswax on a piece of denim.

Sanding edge smooth of custom smartphone case on drum sander.

Sewing Custom Leather iPhone Case

We sew our custom iPhone cases with a strong nylon thread on an industrial sewing machine. If you wanted to make a case yourself, you could use leather sewing tools such as an awl, overstitcher hand tool and an adjustable groover to handsew the hard leather cell case with waxed linen thread.

Sewing leather iPhone case.

Stretching Cellular Case

After the custom iPhone case is finished, we sometimes stretch it a little if we want the phone to be removed a little easier from the leather case. The forming block is placed inside the leather case and then a wooden stick about the size and thickness of a wooden yard stick is inserted between the block and leather to stretch the depth of the leather case. Sometimes we might insert a screw driver down the side of the case to stretch the width. If more space is required, you can dampen with water the inside section of the hard leather cellular case and stretch again with the stick or screwdriver.

Video showing leather cellular case being stretched.

Quality Made Custom Smartphone Cases

Leather artisans such as ourselves take pride in creating our handmade custom smartphone cases. The custom iPhone cases are built to last as they are industrial in strength when compared to what can be purchased in chain stores.